SONAR DOMES

Sonar Dome Design and Production

Sonar dome design and production require considerable knowledge and experience in the field due to the complexity of the technical solution that requires the optimization of the interdependent design parameters.

Sonar Dome

Design and Production Applications

ONUK-BG has been continuously investing in human resources and equipment for developing sonar dome technologies since the year 2007. These investments have paid off by enabling the development and production of sonar domes capable of serving at wide frequency ranges inclusive of high frequencies which are mandatory for mine hunting applications. ONUK-BG Sonar Domes have been succesfully serving on the MİLGEM Corvettes, Engin Class Mine Hunters and New Type Patrol Boats of the Turkish Naval Forces. One of the principal aims of ONUK-BG is to supply the sonar dome needs of the world navies with its technological capabilities and considerable experience in the field.

WHAT IS A SONAR?

Sonar is a device which consists of a transducer; a transmitter and a receiver. Simply, electrical impulse from the transmitter is converted into a sound wave (where electrical energy is converted into acoustical energy) by the transducer and sent into the water. When this wave strikes an object, it rebounds. This echo strikes the transducer, which converts it back into an electric signal. This signal is then amplified by the amplifier and sent to a human interface. Modern sonar utilizes acoustical energy for underwater communication, navigation or detection of submerged objects.

WHAT IS A SONAR DOME?

A sonar dome is an underwater structure mounted to a marine vessel, generally at or near the bow of the vessel. Sonar dome houses sonar transducers and is flooded to acoustically couple the transducers with the surrounding sea. The purpose of sonar dome is to protect sonar transducers from mechanical forces exerted by the seawater through which the vessel moves, to protect the transducers from damage caused by the contact with objects such as piers, and to reduce the self-noise that would otherwise be generated by turbulent water flow past the transducers.

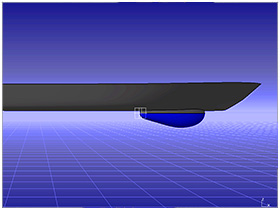

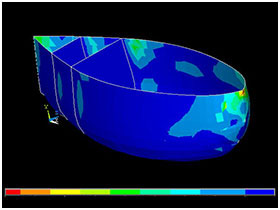

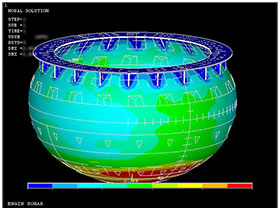

SONAR DOME DESIGN

A dome design is always a compromise between sonar acoustic performance (with respect to dome material, material thickness, dome shape, position of the array inside the dome, baffle, sonar’s out-put power, external noise and anechoic) and mechanical strength to withstand high slamming conditions at sea. The parameters which affect the overall performance of a sonar dome are highly interdependent and complex. Thus sonar dome design and production require considerable knowledge and experience in the field.

WHY FRP COMPOSITES FOR SONAR DOMES?

Conventionally steel and rubber are used for sonar dome constructions. Nevertheless, the superior advantages of Fiber Reinforced Polymer (FRP) Composite materials over conventional materials make FRP Composite materials a far better construction material alternative for modern sonar domes.

Steel Sonar Domes:

- Exhibit good mechanical strength but also exhibit significant difference in characteristic impedance from the sea water thus they show low acoustical transparency,

- In time, due to high slamming loads, they are prone to suffer from permanent local deformations which negatively affect the smooth flow of water around the dome. Turbulence results in additional noise around the dome,

- Exhibit poor corrosion resistance against sea water,

- Require frequent maintenance for corrosion protection which incurs additional costs.

Rubber Domes:

- Have their characteristic impedance closely aligned with that of sea water which results in good acoustical transparency,

- However, exhibit poor mechanical strength, they have to be reinforced and pressurized,

- Require special and expensive manufacturing investment,

- Generally on site repair is not possible,

- Short service life due to deterioration of the material in time.

FRP Composite Sonar Domes:

- Far better acoustical performance (under the condition of an adequate design and application of an adequate production technology),

- High strength to weight ratio,

- No plastic deformation under stress,

- Fatigue and impact resistance,

- Reduction in additional noise and vibration,

- Low resonance,

- Corrosion proof,

- Good characteristic impedance,

- Long service life,

- Elimination of constant need for surface treatment and repairing,

- On site repairing is generally possible.

Features

of

ONUK-BG Sonar Domes

The outstanding features of the Sonar Domes which are developed and produced by ONUK-BG are as follows:

- High acoustic transparency (6kHz-500kHz frequency range),

- High structural strength,

- Low self noise and vibration,

- High fatigue and impact resistance,

- Lifetime geometric stability,

- High dimensional precision,

- Easy maintenance,

- Long service life,

- Low operational cost,

- High corrosion resistance,

- Possibility of on-site repair in case of damage,

- Low weight,

- Platform specific technical solutions.

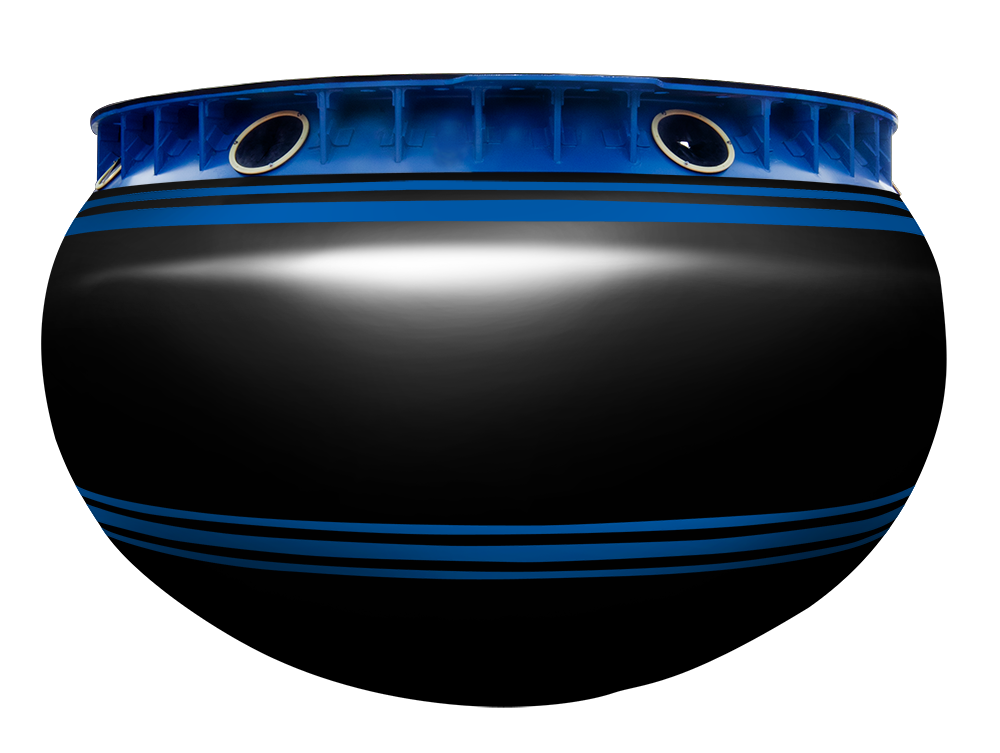

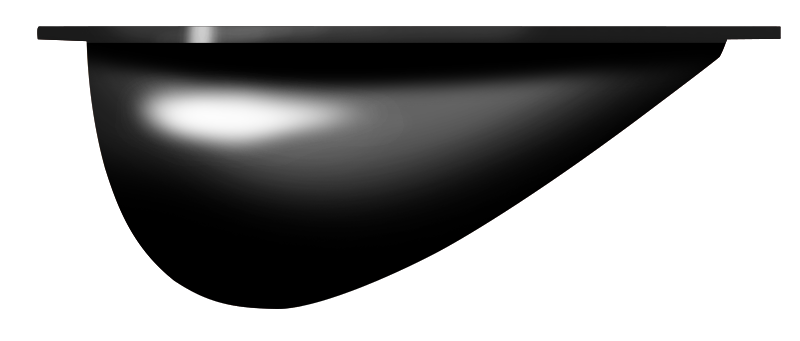

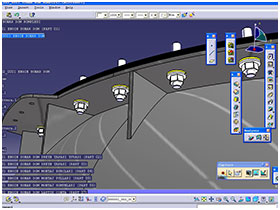

MİLGEM Corvette Sonar Dome

The MILGEM Sonar Dome has been developed and produced by ONUK-BG to be utilized on MILGEM Corvettes which have been designed and built for anti-submarine warfare and patrol missions.

In order to meet the demanding structural strength and acoustical performance requirements nano-enhanced Fiber Reinforced Polymer (FRP) Composite materials have been exploited as the construction material.

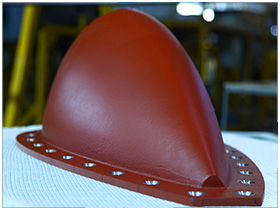

HMS Sonar Dome

It was designed and produced as the main part of the Underwater Equipment Group of the Integrated Sonar System developed within the scope of an international R & D project.